From Us Announcement and News

By following the latest technologies and designs, we always offer our new and innovative products to our customers. Follow us to stay one step ahead in our announcements, special campaigns and the latest developments in the industry.!

Today, occupational safety in logistics and transportation sectors is a cri...

13.03.2025

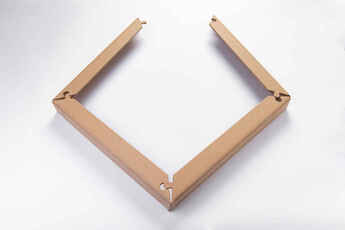

While carrying any product from one place to another, it is almost impossib...

16.04.2023

Inflatable pillows used for securing cargo transported by air, land and sea...

16.04.2023